Factory Cheap Hot Eps Foam Cutting Machine - Semi-automatic Type Forming Machine – Xiongye

Factory Cheap Hot Eps Foam Cutting Machine - Semi-automatic Type Forming Machine – Xiongye Detail:

Product Introduction

• It adds Programmable Logic Controller (PLC) system on the basis of common forming machine, which adopts the advanced electronic and pneumatic components, and operation can be changed automatically and manually. It is the middle start and may change heating methods according to forms of product.

• It lowers technical requirements to operators and all operations can be controlled by PLC.

• Simultaneously feeding of multi feeding inlets greatly saves the feeding time.

• Time for the whole cycle of material feeding, heating, cooling and demoulding is accurate and stable. It saves time, reduces cost, improves economic benefits as well as develops quality of product.

• It also reduces work intensity and operations so that one person is able to operate several machines.

Technical Parameter

|

Item |

Unit |

PSB120 |

PSB140 |

|

Workbench |

mm |

1200*1000 |

1400*1200 |

|

Largest Mould size |

mm |

1000*800 |

1200*1000 |

|

Max.Travel |

mm |

900 |

900 |

|

Steam Pressure |

Mpa |

0.6-0.8 |

0.6-0.8 |

|

Compressed Air Pressure |

Mpa |

0.6-0.8 |

0.6-0.8 |

|

Installed Power |

Kw |

3.0 |

4.0 |

|

External Dimension |

mm |

1800*1350*2650 |

2000*1550*2950 |

|

Installed weight |

kg |

1500 |

2000 |

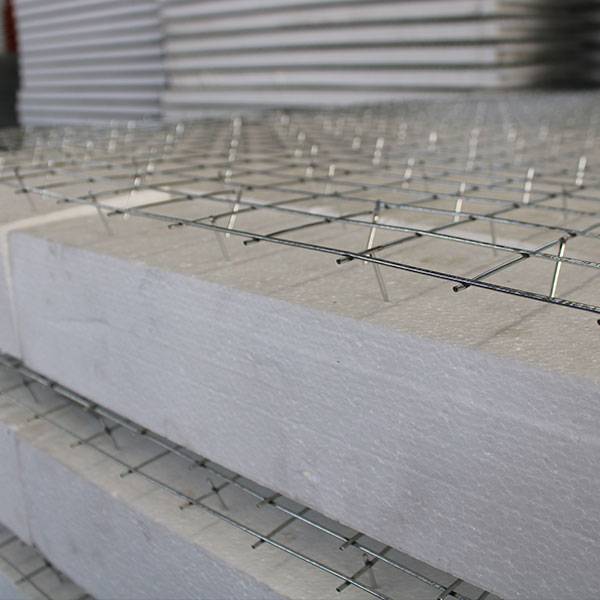

EPS Shape Molding Machine is mainly used to produce EPS foam packaging box , ICF block , block concrete insert, floor hollow block , hourdis,lost foam casting, decorative cornice , ceiling board, column, helmet,etc

The machine can different size eps product, box, package, tray, etc. We already sell the machine more than 100 countries, have a good fame. All the client like the design and stable quality.

Our company have more than 30 years history in this field, our brand is CHX, we located in North Area, Nanlv Industrial Zone,Xinji City ,Hebei province,China. More than 3000m2 workshop, more than 200 workers, 20 engineers. 10 special for design and improve new machines. Really glad if you could visit our factory when you free. Hope have a long cooperation with your company.

Product detail pictures:

Related Product Guide:

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Factory Cheap Hot Eps Foam Cutting Machine - Semi-automatic Type Forming Machine – Xiongye , The product will supply to all over the world, such as: Vietnam, Turin, Marseille, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.