OEM/ODM Factory Shape Moulding Machine - Coating machine – Xiongye

OEM/ODM Factory Shape Moulding Machine - Coating machine – Xiongye Detail:

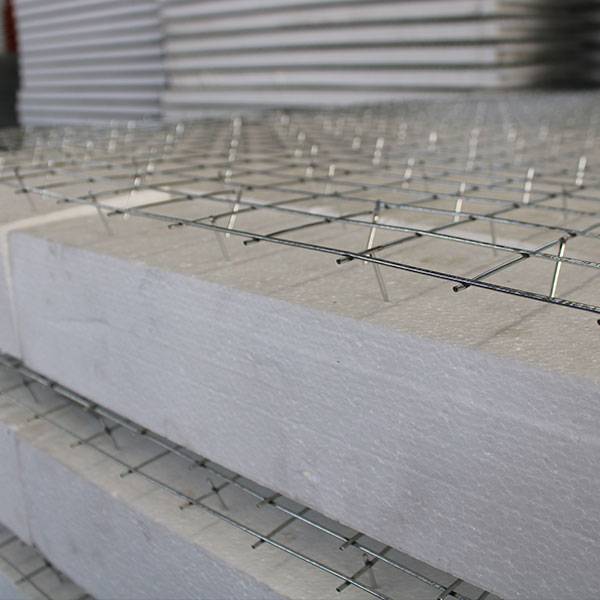

EPS Foam coating machine is very important machine as hot wire CNC foam cutting machine, for the companies, which produce decorative architectural foam shapes. The surface of the decorative models, which has sliced by EPS blocks, should be coated with foam coating machine, for protect the building surface from corrosive weather conditions (like rain, snow, hail, storm and temperature differences between day and night)

For example, you can’t gain first quality product if your foam coating machine or your mortar is wrong even if you use the best quality foam cutting machine of the world.

Therefore, all machines in your factory have important equally. It is very important for your company’s achieve that you to buy the machines which are compatible and can be integrated each other.

shops exterior decorating the ideal choice.

EPS Foam Coating Bussiness

If you want to create a business which is competitive and would have great growing percentage in construction industry market, you need to produce the final products with acceptable quality.

As is known, the product should be visibly qualified for settling into the good space in your target market. So the most important thing is the surface of your decorative foam shapes model should be completely smooth and clear. Also its corners should be explicit and straight. And the last there should not be any appeared bubble on the surface of products. You should care those conditions to increase the performance of your foam coating machine.

Foam Coating Thickness

Now, you have general knowledge about foam coating so let’s tell you about a top level technical knowledge.

That how many millimeters mortar coated on to foam is as very important as quality of mortar on the foam while manufacturing decorative exterior profiles and other exterior products.

You can do coating as much as you want between 1 millimeter and 10 millimeters using our foam coating machine. (The commonest mortar thicknesses of exterior products which are preferred in good quality and economic product class around the world are 2 mm/3 mm and 4 mm.) It is not a correct approach the think that “product which has been coated thickly is always good quality.”

Standard machine date please connect with us, or leave a message, will send you soon.

Product detail pictures:

Related Product Guide:

We are commitment to offer you the aggressive price tag ,exceptional products and solutions high-quality, as well as fast delivery for OEM/ODM Factory Shape Moulding Machine - Coating machine – Xiongye , The product will supply to all over the world, such as: New Orleans, Vietnam, Qatar, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!